Forum Manufacturing-X

Data space for Industry 4.0

Industry 4.0 needs easily available, secure and consistent data networking. Manufacturing-X is designed to make this possible. The goal is to establish a data ecosystem that enables trustworthy data exchange between companies based on open standards and offers companies digital sovereignty.

Manufacturing-X is intended to make the added value of digital technologies such as the Internet of Things (IoT), artificial intelligence (AI) and machine learning even more usable in order to develop new business models and increase the competitiveness of industry.

shutterstock

Collaboration

The Manufacturing-X Forum was founded on April 1, 2024, replacing the VDMA's Industry 4.0 Forum, which had been in existence for ten years. With the establishment of the Manufacturing-X Forum, we are bundling and coordinating all activities on this topic within the association, as well as towards our members, thus taking into account the increasing importance of data rooms as an important basis for new, digital business models.

The Manufacturing-X forum also serves as a bridgehead to relevant initiatives, projects and organizations, such as the national Industry 4.0 platform or the Catena-X association. The VDMA is an active partner in the Factory-X, SCALE-MX, RoX, Wind-X, Fluid 4.0 and SM4RTENANCE projects, which thematically contribute to Manufacturing-X and data ecosystems. The projects are largely funded by the Federal Ministry for Economic Affairs and Climate Protection with DARP funds (financed by the European Union - NextGenerationEU). Further project participations to establish this decentralized ecosystem could follow. The Manufacturing-X Forum has set itself the following tasks for an internal focus on the topic and for our members:

- Representing the interests of our members in the development of Manufacturing-X

- Formation of a VDMA-wide bracket on the topic of Manufacturing-X

- Bundling, coordination and alignment of all activities within the VDMA

- Information, knowledge transfer and exchange of experience

- Networking of the organizational units involved in Manufacturing-X

- Support and referral for member inquiries

Your contact - more contacts at the end of this page

The machinery industry is calling for a thorough state reform in Germany to increase industrial competitiveness. The EU, too, must get the economic development in Europe back on track.

VDMA and T-Systems, together with the umati initiative, are presenting the first global Manufacturing-X solution with open standards for machine data at this year's Hannover Messe.

Find out where you can get information from the VDMA

Hannover Messe will be a showcase for the digital data economy. In the Manufacturing-X forum, the VDMA will present trustworthy data rooms and innovative X projects from various industrial sectors.

Take part in our survey and let us know what you know and think about Manufacturing-X and the opportunities of a data-driven ecosystem.

The joint project RoX is dedicated to building a digital ecosystem that enables the use of innovative AI-based robotic solutions in practice-relevant applications and industries.

Digital transformation is becoming a key issue for success in mechanical and plant engineering. The new short study "Success factors of digital business models" highlights options for action for companies.

The IMPULS study "Tokenization in mechanical engineering" published today analyses Web3 technologies that promise the industry efficiency gains, new financing models and innovative monetization opportunities.

Industry expects a 16% drop in sales; companies must implement the Cyber Resilience Act; VDMA's Manufacturing-X report

The document "Players in the industrial data economy" shows which companies are involved in which projects relating to the data economy. The aim is to enable better networking and learning from each other - both throughout Germany and in Europe.

Focus on the data economy: the launch of the SCALE-MX transfer project aims to disseminate the results of the Manufacturing-X projects across industry.

The topic of Manufacturing-X is now of interest to many of our member companies. We receive many questions, which we have compiled and answered here.

Our event overview shows you where you can meet our data room experts.

In 2024, the VDMA and the ZVEI are once again organizing a forum for the SPS, the "Technology Stage powered by VDMA/ZVEI" with many interesting presentations and panel discussions.

What is behind the X in Manufacturing-X? A groundbreaking concept that goes far beyond the exchange of data between companies. It is the key to collaboration within and between industries.

Meet the digitization experts at the VDMA Software and Digitization stand to exchange experiences.

With the establishment of the VDMA Forum Manufacturing-X, the VDMA is bundling and coordinating all activities on this topic for its member companies and stakeholders.

Industry 4.0 has given German and European industry a leading role in automation. Now it's all about the world of digital business models and secure data exchange. The concept is called "Manufacturing-X".

On the occasion of the Mechanical Engineering Summit 2023, Produktion magazine asked Hartmut Rauen about Manufacturing-X. In the interview, the Deputy Managing Director of the VDMA explains what it is all about.

What could a data space for Manufacturing-X look like in the future and what is important? The VDMA and ZVEI's blueprint study provides an impetus for this.

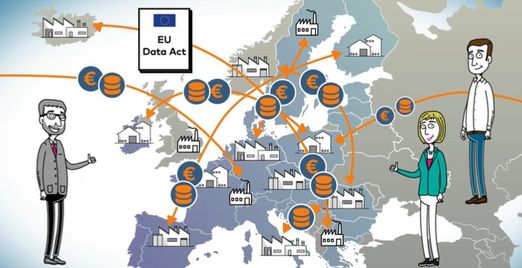

With the Data Act, the European Commission is aiming for a new legal framework for data use, utilization and distribution. The new study provides recommendations for action for the mechanical and plant engineering sector.

The trade association started the development of Companion Specifications in the field of textile machinery in 2019. As the first project, the Compainon Specfication "OPC UA for Fibre & Yarn Testing Devices" has now been published as a Release Candidate.

Connectivity is a key component for the successful technological and economic development of economies, and thus for social prosperity.

Increasing geopolitical conflicts, trade wars, as well as massively disrupted supply chains since the beginning of the Corona pandemic: these are the main drivers of the calls for technological sovereignty in Germany and Europe that have become louder in recent years. But what is this actually?

In order to remain at the technological forefront and enable climate protection, the world of production must change. It needs more knowledge about all processes and materials in the value network, and it needs more cooperation toward a sovereign production location in Europe. The "Manufacturing-X" initiative is intended to make this possible.

Examples of remote maintenance architectures show how mechanical and plant engineering can ensure secure service from a distance.

What challenges do companies face in dealing with the platform economy? What demands do customers of machinery and plant manufacturers place on digital products and services? In the new episode of the VDMA Industry Podcast, Dr. Julia Duwe, Head of Global Architecture at Trumpf Werkzeugmaschinen and Dr. Stefan Schunck, Head of Digital Products at Krones AG, explain how this change can be shaped.

With increasing networking, new approaches are needed in companies. Not just a view of the machines is needed, but a strong view of the entire ecosystem.

New episode of the podcast by OPC Foundation about OPC UA for Machinery and why its the most critical and important base class of all VDMA information models. It will become critically important and mandatory not only for machines, but also for all services that access data.

The basis for a successful digital transformation is a strong digital infrastructure - which Germany does not have. Regardless of whether it's mechanical engineering, industry or the skilled trades: in order to remain competitive, hardly any manufacturing company today can do without the potential of digitalization.

State Association Day: OPC UA - Tackling and Implementing

Cooperation within Europe on digital policy must improve. The industry needs efficient political structures and competent contacts. And it needs a common, interoperable cloud and data infrastructure.

The regional associations of the VDMA offer information events on OPC UA in June.

The VDMA study "Interoperability in Machinery and Plant Engineering" highlights the relevance of interoperable interfaces and associated standards in companies.

umati stands for "universal machine technology interface". It forms the framework for the worldwide distribution of interface standards based on OPC UA in mechanical and plant engineering.

OPC UA for Machinery as a basic specification for mechanical engineering

VDMA Working Group Additive Manufacturing launches OPC UA activity

Germany has created a brand and an export hit with Industrie 4.0. The consequence: China is staking its claim with its own initiatives. The opportunities for the German mechanical engineering industry must be carefully explored.

The guide "Successfully marketing digital offerings" presents four success models of digital service types: the integral product improvement, the complementary service, the digital intermediary and the digital innovation. They make it easier for VDMA members to classify their own digital services.

Interoperability is a key pillar of efficient digital transformation and the long-term positioning of every company in the global market. Stay up to date with our newsletter.

OPC UA is an important building block in defining the world language of production. Find out what the benefits and challenges are in the video of the panel discussion with experts from industry and the OPC Foundation.

How do companies manage to successfully introduce digital innovations? A VDMA study provides answers to this question by identifying important fields of action for future-oriented leadership.

The VDMA accompanies and supports its members on the way to Industrie 4.0. Here you will find an overview of the current publications on the topic.

An overview of research institutions in the field of artificial intelligence is provided by the Learning Systems Platform initiated by the Federal Ministry of Education and Research (BMBF) in cooperation with the Federal Ministry for Economic Affairs and Energy (BMWi).

The collection "Industrie 4.0 Research at German Research Institutes" offers VDMA members an overview of the German research landscape in this field. In the 2019 edition, around 40 universities and institutes present their current projects.

The working group "Research I40 and AI" aims to initiate cross-industry research projects on Industry 4.0 and AI. Interested member companies can participate in the topics.

The Industrial Collective Research (IGF) represents a unique innovation platform for small and medium-sized enterprises. As an open-topic and industry-driven program, IGF is an important component in pre-competitive research for mechanical and plant engineering.

With the target image of Industry 4.0 and digital business models in mind, it is a central task of mechanical and plant engineering to network production interoperably. The challenge here is to achieve interoperability between a wide variety of machines, components and systems.

Digitalization and networking are changing the function and life cycle of machines and systems. The availability of machine and component data in the form of a uniform language is the key to productivity advances. Interoperable communication in production is a foundation for this. Machines and plants must be able to exchange data without obstacles. This is the only way intelligent and networked production can function.

Industry 4.0 requires changes at all company levels and across the entire value chain. Industry 4.0 is associated with a new way of thinking in the organization of processes. In the end, what counts for companies is added value. The question of economic efficiency is coming into focus, and with it the topic of interoperability.

Events

The seamless exchange of data across manufacturers, technologies, and industries is the foundation for innovation, efficiency, and long-term competitiveness. Take the opportunity to present your latest findings. Submit your contribution by 30 September 2025.

Exclusively for VDMA members

Register now and read more

Don't have an account?

If your company is already a VDMA member, you can register easily.

Do you not know whether your company is already a member? Take a look at our member list and find out.

Are you interested in becoming a VDMA member?

Your contact

.jpg/c4243702-eaf7-ebc0-468b-0cf26b5a76fc)

.jpg/d0e19405-95cc-cdcd-b94f-23e98fcb0013)

.jpg/4c3ed308-a337-a469-6f39-de8a358108c0)

.jpg/73098e34-fa44-a31a-2b7b-9f468c59aa7a)

.jpg/48d5ba95-761c-6e1b-2afc-8a702a5fc622)